The Science Behind Sterile Filtration for GLP-1 Weight Loss Drug Production

In the dynamic world of pharmaceutical compounding, especially for weight loss medications like GLP-1 receptor agonists, filtration is paramount in ensuring both drug quality and safety. This blog explores the integral science of pharmaceutical filtration and its critical impact on the quality of GLP-1 drugs, providing essential insights for compounding pharmacists and healthcare professionals.

What is Sterilizing Grade Filtration for GLP-1 Drugs?

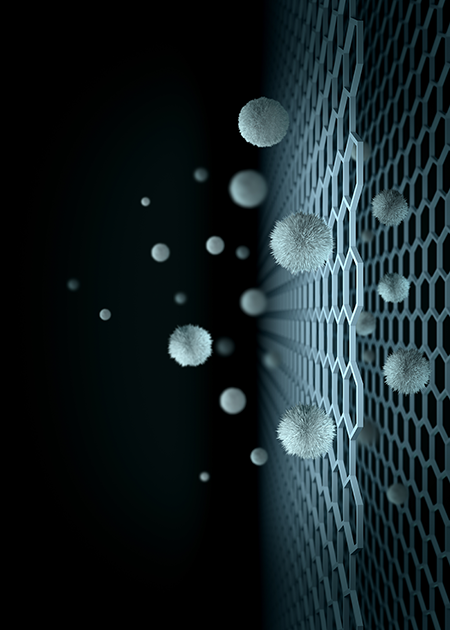

Sterilizing grade filtration is vital in the compounding and preparation of peptide-based GLP-1 medications. It effectively removes particulates, microorganisms (achieving retention of Brevundimonas diminuta (≥10^7 CFU/cm²) consistent with ASTM F838-20 standards), and other contaminants, thereby ensuring the sterility and purity of the drug solutions.

The significance of robust filtration systems in maintaining the quality of weight loss drugs cannot be understated. GLP-1 receptor agonists, such as semaglutide and tirzepatide, are intricate peptide molecules that necessitate meticulous handling and processing. Appropriate filtration not only maintains the integrity of these compounds but also minimizes contamination risks, ensuring that the final products adhere to the most stringent quality and safety standards.

Types of Filters Used in Pharmaceutical GLP-1 Compounding

Pick the Right Membrane for Sterilizing Grade Filtration: Membrane filters are commonly employed in pharmaceutical compounding. Polyethersulfone (PES) Sterilizing Grade Membranes are particularly favored for GLP-1 filtration due to their low protein binding properties and high flow rates, which are crucial for maintaining the efficacy and purity of peptide drugs.

Filtration Techniques for GLP-1 Compounding

Pick the Right Size for Sterilizing Grade Filtration:

• Disc Filters

These compact filters are excellent for smaller volume filtrations. The PureFlo® D50 Disc Filter (0.65μm/0.2μm) can handle volumes from 175 mL to 980 mL, optimized at 500 mL, providing an effective filtration area of 15.9 cm². The PureFlo® D25 Disc Filter (0.2μm) is ideal for volumes ranging from 60 mL to 200 mL, optimized at 100 mL, with an effective filtration area of 4.5 cm². These specifications make them particularly suitable for GLP-1 compounding.

• Capsule Filters

For larger-scale filtration needs, capsule filters like the PureFlo® JKP Capsule Filter (0.65μm/0.2μm) are perfect. With a substantial effective filtration area of 260 cm², this filter can manage volumes from 3L to 12L, optimally at 5L, making it ideal for batch processing in pharmaceutical applications.

The Process for Semaglutide or Tirzepatide Preparation

The preparation of peptide-based medications like semaglutide and tirzepatide involves several critical steps, with sterilizing grade filtration being essential to ensure the highest drug quality and safety:

• Dissolution: The process begins with the dissolution of the crude peptide in a suitable buffer solution, preparing it for the critical filtration stage.

• Sterilizing Filtration: For the filtration step, our state-of-the-art, highly unique, advanced Asymmetric Dual Layer 0.65μm/0.2μm membrane technology is employed. This innovative filter design incorporates a two- stage filtration mechanism in a single unit:

o Pre-filtration Layer (0.65μm): The larger pore size layer acts effectively as a pre-filter, capturing larger particulates and extending the life of the subsequent finer filter layer, thereby enhancing the overall efficiency and cost-effectiveness of the filtration process.

o Sterilizing Grade Layer (0.2μm): The finer 0.2μm layer provides the critical sterilizing grade filtration needed to ensure the removal of all microorganisms and other contaminants, maintaining the purity and integrity of the peptide solution.

This dual-layer setup not only optimizes filtration efficacy but also eliminates the need for a separate pre- filtration step, simplifying the process and reducing potential contamination risks.

• Aseptic Handling: Pre- and Post-Filtration Processes: It is imperative to handle the sterile solution aseptically both before and after filtration to ensure that its sterility is maintained all the way through to administration. To support this essential requirement, International Filter Products offers an integrated suite of sterile handling solutions:

o Sterile Tube Set for Fluid Transfer: This component is crucial for the safe and sterile transfer of fluids throughout the compounding process, minimizing the risk of contamination.

o Sterile EVA Bags and Sterile Syringes for Storage: Our sterile Ethylene Vinyl Acetate (EVA) bags and syringes are specifically designed for the secure storage of pharmaceuticals, ensuring that the prepared medications remain uncontaminated and ready for administration.

These products are meticulously designed to support the highest standards of aseptic handling, ensuring that the medication not only remains safe for patient use but also meets all regulatory standards for injectable pharmaceuticals.

Important Considerations for Peptide-Based Drugs:

• Shear Sensitivity: GLP-1 peptides are susceptible to shear stress, which can degrade the peptides. Filters with appropriate pore sizes and flow rates are crucial to minimize this risk.

• Adsorption: Some filter materials may adsorb peptides, potentially reducing drug efficacy. PES membranes are preferred for their low protein-binding characteristics.

• pH and Solvent Compatibility: The chosen filters must be compatible with the pH and solvents used in GLP-1 formulations to avoid adverse interactions.

Conclusion

Ensuring the use of proper sterilizing grade filtration is crucial in the compounding of GLP-1 drugs like semaglutide and liraglutide. This process not only removes contaminants but also maintains sterility and preserves the integrity of these complex peptide molecules. Compounding pharmacists can significantly improve the quality and safety of GLP-1 medications by selecting the appropriate filters and adhering to precise filtration techniques.

At International Filter Products, we offer a diverse range of high-quality filters specifically designed for pharmaceutical compounding, including GLP-1 drugs. Our PureFlo® series of disc and capsule filters ensure reliable sterilizing grade filtration, helping your compounded medications meet the highest quality and safety standards.

For more detailed information on our products and how they can enhance your GLP-1 compounding processes, please visit our website or contact our expert team.