Gerresheimer 6R / 6 mL Amber Sterile Vials – ISO Standard Type I

Items must be purchased in nests of 48 units.

The Gerresheimer 6R / 6 mL Amber Sterile Vial, made from premium ISO Standard Type I Borosilicate Gx® Elite glass, is purpose-built for sterile compounding excellence. Its amber tonality ensures optimal protection for light-sensitive formulations, while Ready-To-Fill (RTF®) processing guarantees that every vial is washed, depyrogenated, sterilized (ETO or VHP), and packaged under cGMP cleanroom conditions.

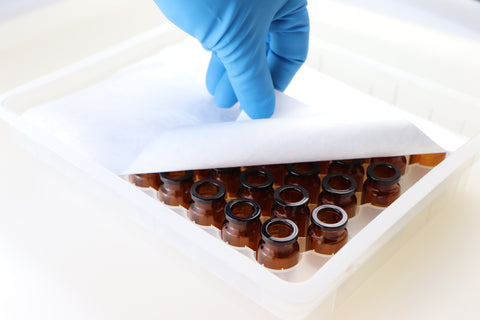

Delivered in double-bagged EZ-fill® trays with nest & tub packaging , these vials minimize glass-to-glass contact, streamline aseptic workflows, and reduce breakage rates. Combined with Gx® Elite glass technology—offering superior strength, flawless cosmetic quality, and validated regulatory compliance—they are the trusted choice for 503A/503B compounding pharmacies, biopharmaceutical manufacturers, and clinical fill-finish operations.

1 Nest & Tub = 48 units; 5 packs = 240 units (10 less than a complete 250-unit batch). These vials provide nearly a full 250-unit batch while minimizing glass-to-glass contact.

Relevant Industries

• Sterile Compounding Pharmacies (503A / 503B)

• Biopharmaceutical Manufacturing

• Clinical Research & Fill-Finish Facilities

• Vaccine and Biologics Production

Applications

• Aseptic preparation of sterile injectables

• Packaging of light-sensitive biologics (hormones, peptides, vaccines)

• Ready-to-Fill use in laminar flow isolators

• Batch sterile compounding requiring consistent vial quality

• Volume Capacity: 5 mL nominal (Brimful ~6.68 mL)

• Neck Finish: ISO 20 mm crimp neck

• Color: Amber – protects against UV/light degradation

• Material: ISO Standard Type I Borosilicate Glass (high chemical resistance)

• Packaging Configuration:

a) 1 Nest & Tub = 48 Vials

b) 5 Packs = 240 Vials (10 less than a 250-unit full batch)

• Sterilization Method: Ready-to-Fill (ETO or VHP)

• Dimensions: Ø 22.0 mm × H 40.0 mm (ISO 8362-1 Standard)

• Compatibility: Suitable with 20mm stoppers & seals

• Sterility Assurance: Compliant with USP <71> Sterility Tests

• Endotoxin Control: Meets USP <85> Bacterial Endotoxin requirements

• Residual Testing: Verified per ISO 10993-7 (ETO residuals)

• Glass Standards: Complies with USP <660>, Ph. Eur. 3.2.1, and JP for hydrolytic resistance

• Container Closure Integrity (CCI): Fully validated for sterile compounding workflows

• Defect Rate: Cosmetic defect reduction >90% with Gx® Elite glass inspection

• Documentation Supplied: Certificate of Conformance (CoC), Certificate of Analysis (CoA), Sterility & Endotoxin Reports

• Shelf Life: 3 years under recommended storage

Need technical support or help with a quote? Contact Us.

| Component | Material | Properties / Features |

| Transparent Peelable Polymer Lid | Opaque HDPE/PE |

|

| Gx® Elite Glass Vials | Type I Borosilicate Glass |

|

| Nest | Polypropylene Homopolymer |

|

| Tyvek Stripes | HDPE |

|

| Tub | High Impact Polypropylene Peterophasic Copolyme |

|

| Boxes | Polypropylene |

|

| Sterilization | ETO |

|